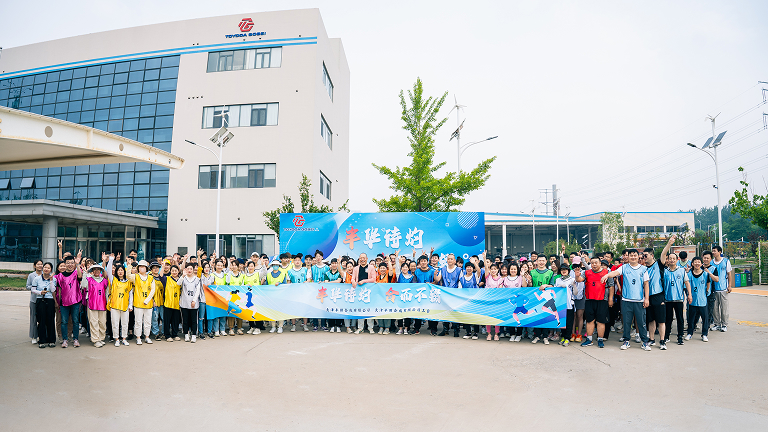

Growing together through activities with all stakeholders

In 2025, we mark our 30th anniversary of entering the Chinese market. Over the past three decades, with strong support from local governments at all levels, our operations in China have achieved steady development and rapid growth. We have not only created numerous employment opportunities but also made significant contributions to local economic development and tax revenue growth.

Guided by the principle of "rooted in the community, giving back to society," we have actively participated in social welfare initiatives. In response to natural disasters such as earthquakes, torrential rains, and floods, we have promptly heeded government calls by donating funds and supplies to support post-disaster recovery efforts. Additionally, during traditional festivals, our sites organize employee visits to nursing homes and welfare institutions, conducting charitable activities to spread warmth and care.

As Toyoda Gosei's core representative in China, TG China remains committed to its mission of "growing with China and serving society." We will continue to work hand in hand with government authorities, customers, suppliers, and community members to pursue shared progress. Moving forward, we will continue to fulfill our corporate social responsibilities and contribute to sustainable social development.

Environment

Environment

Social

Social

Governance

Governance

CSR

CSR